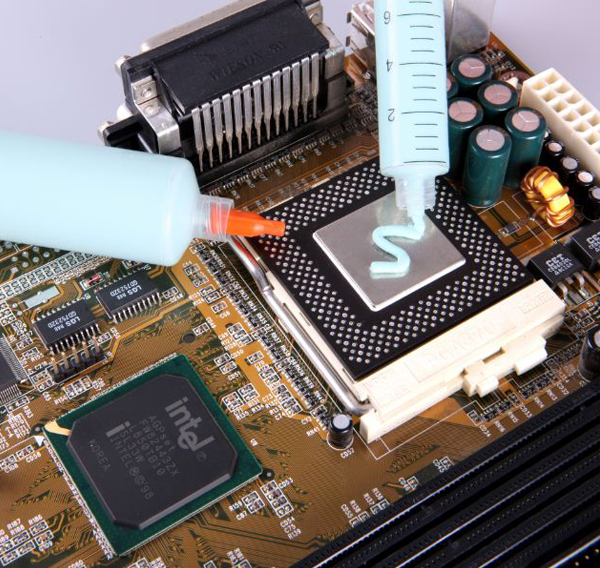

Thermal Gel

Thermal Gel is a soft, single part, silicone putty thermal gap filler in which no cure is required. This gap filler is designed to be used in where large gap tolerances are present and low mechanical stress on delicate components are needed.

Brothers’s Thermal Gel has a composition which yields superior thermal performance and super compliancy. This material transfers little to no pressure between interfaces. Specialized rheology allows for easy flow under pressure.

Product Features

▪ Soft and compliant transferring little to no pressure between interfaces

▪ TP 200,350 & TP 300 offer high thermal conductivity with standard dielectric performance

▪ TP500 offer better performance with good dispensing speed which applied in high thermal management requirements

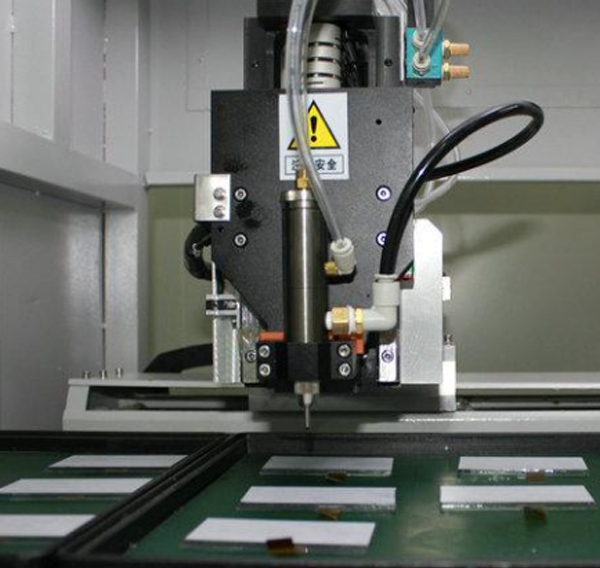

▪ Easily dispensable

▪ Fully-cured

▪ Low thermal resistance

Typical Applications

▪ Heat Sink / Chassis

▪ Memory Modules

▪ Server and Network Equipment

▪ Large Storage Device

▪ Automotive Electronics

▪ Communication Equipment

▪ Power Supplies

▪ LCD Display

Technical Specification

|

Performance |

Thermal Gel |

Test Method |

|||||

|

TP200 |

TP350 |

TP350 |

TP500 |

TP600 |

|||

|

Physical |

Color |

White |

Green |

Grey |

Grey |

Grey |

Visual |

|

Density (g/cc) |

2.3 |

2.9 |

3.0 |

3.1 |

3.1 |

ASTM D792 |

|

|

Flow Rate (g/min) |

25 |

25 |

45 |

25 |

16 |

2.0mm @ 90Psi |

|

|

Hardness (shore 00) |

<10 |

ASTM D2240 |

|||||

|

Bondline Thickness (mm) |

0.1 |

0.2 |

|||||

|

Thermal |

Thermal Conductivity (W/m.k) |

2.0 |

3.5 |

4.0 |

5.0 |

6.0 |

ASTM D5470 |

|

Operation Temp. (℃) |

-55~200 |

/ |

|||||

|

Electric |

Breakdown Voltage (KV/mm) |

>5 |

ASTM D149 |

||||

|

Volume Resistance(ohm-cm) |

>1013 |

ASTM D257 |

|||||

|

Regulatory |

Flaming Rate |

V0 |

UL94 |

||||

|

RoHS |

Compliance |

/ |

|||||

|

Shelf Life(months) |

24 |

/ |

|||||

TPt is two components thermal gel. Two components can be mixed during dispensing in 1:1 ratio. Material can be cured at room temp. or high temp., to a sheet like thermal pad, which can be easily removed or maintained. Meanwhile, a solid pad after two-component gel curing are more stable, especially in vibration application

|

Typical Performance |

TP200t |

TP400t |

Test Method |

|

|

Physical |

Color/Component A |

White |

White |

Visual |

|

Color/ Component B |

Blue |

Red |

Visual |

|

|

Flow Rate |

50 |

50 |

2.0mm @ 50Psi |

|

|

Hardness(shore 00) |

40 |

60 |

ASTM D2240 |

|

|

Thermal |

Thermal Conductivity (W/m.k) |

2 |

4 |

ASTM D5470 |

|

Operation Temp. after Curing(℃) |

-55~200 |

/ |

||

|

Electric |

Breakdown Voltage (KV/mm) |

>5 |

ASTM D149 |

|

|

Curing |

Pot life@ 25 ℃ (min) |

120 |

||

|

Curing @ 25 ℃ (hrs) |

6-8 |

Rheometer- time to read 90% cure |

||

|

Curing @ 100 ℃ (min) |

20 |

|||

188-2226-7107

TIANJIN BROTHERS TECHNOLOGY CO., LTD.

Tel: 18822267107

Email:gavin.ma@brothers-tech.com

PRODUCTS

PRODUCTS